Efficient and versatile, the Parts Diverter from Harvard Factory Automation (HFA) ensures seamless part sorting and distribution across production lines, boosting productivity and reducing downtime.

Harvard Factory Automation’s Parts Diverter is a state-of-the-art solution for sorting and distributing parts efficiently in industrial environments. Designed to streamline operations, it enhances workflow and minimizes manual handling, making it an essential component for industries relying on precise and rapid part distribution.

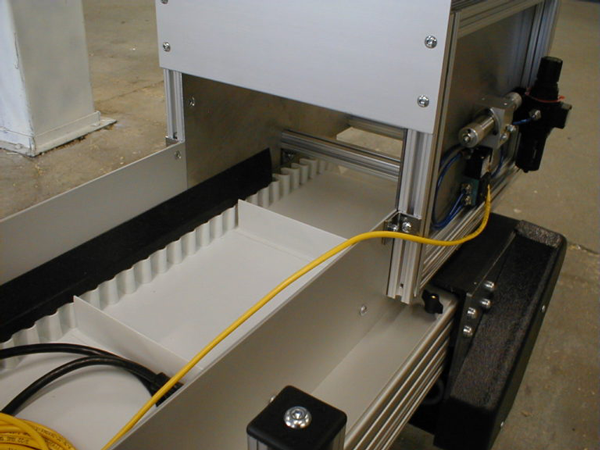

The Parts Diverter from HFA features durable construction, customizable configurations, and seamless integration with existing conveyor systems. It offers precise sorting, automated part handling, and adjustable settings to suit diverse industrial needs. These features ensure high efficiency and reliability for any production environment.

The Parts Diverter increases productivity, reduces errors, and enhances safety by automating part distribution. Its adaptability to various industries and processes makes it an invaluable tool, optimizing operational efficiency and lowering labor costs.

Click the dropdowns below to view detailed information for each model in the Parts Diverter Series.

| Parts Diverter Specifications | |

|---|---|

| Application | Automatically diverts reject shots, QC samples, and facilitates filling two containers. |

| Mounting Options | Under-press conveyors, stand-alone setups, or at the discharge end of incline conveyors. |

| Available Sizes | Multiple sizes with customizable widths to suit specific requirements. |

| Construction Material | Stainless steel side plates with UHMW trays; anodized extruded aluminum frame. |

| Actuation | Pneumatic rotary actuator. |

| Electrical Options | 24 VDC or 110 VAC solenoid with filter regulator; compatible with dry contact signals. |

| Cleanroom Compatibility | Yes; designed with no painted components to meet cleanroom standards. |

A: The Parts Diverter is ideal for manufacturing, automotive, electronics, and packaging industries requiring precise part sorting and distribution.

A: Yes, HFA offers customizable configurations to meet specific industry and application requirements.

A: It seamlessly integrates with conveyor systems, ensuring minimal disruption and quick setup.

A: Yes, it is designed for durability and ease of maintenance, reducing downtime and operational costs.

A: Absolutely, the diverter accommodates a range of part sizes, offering flexibility for different production needs.