The PNX-III Series from Nissei delivers quick mold changes, flexible clamping, superior efficiency, enhanced safety, and budget-friendly options, ideal for boosting injection molding productivity.

The Nissei PNX-III Series is a hybrid injection molding solution combining the reliability of hydraulic systems with the energy efficiency of electric technology. Powered by Nissei’s “X-Pump” system, it delivers precise performance, quick response times, and versatility for various production needs, making it a top choice for manufacturers seeking efficiency and sustainability.

The Nissei PNX-III Series combines energy efficiency with precision using its advanced “X-Pump” system, which minimizes power use while delivering fast, accurate molding. With a durable hybrid design, low maintenance needs, and versatile application support, it’s perfect for manufacturers prioritizing performance and sustainability.

The PNX-III Series offers cost efficiency, consistent quality, and scalable performance, making it ideal for both small and large-scale production. With user-friendly controls, sustainable technology, and Nissei’s trusted design, it streamlines operations while enhancing productivity and profitability.

Click the dropdowns below to view detailed specifications for each model in the PNX-III Series.

| Item | Unit | 2A | 5A (std) |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.63 (16) B: 0.75 (19) | A: 0.87 (22) B: 1.02 (26) BB: 1.10 (28) |

| Injection Capacity | inch³ (cm³) (oz) | 0.79 (13) (0.44) 1.1 (18) (0.6) | 2.1 (35) (1.2) 3.0 (49) (1.6) 3.5 (57) (1.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 39820 (274) (2800) 30930 (213) (2175) | 40100 (276) (2820) 30290 (209) (2130) 26170 (180) (1840) |

| Clamping Force | USton (kN) (tf) | 45 (405) (41) | |

| Clamping Stroke | inch (mm) | 11.8 (300) | |

| Min. Mold Thickness | inch (mm) | 6.7 (170) | |

| Max. Daylight Opening | inch (mm) | 18.5 (470) | |

| Tie Bar Clearance (H×V) | inch (mm) | 12.2 x 12.2 (310 x 310) | |

| Die Plate Dimensions (H×V) | inch (mm) | 17.7 x 17.7 (450 x 450) | |

| Ejector Stroke | inch (mm) | 2.4 (60) |

| Item | Unit | 5A (std) |

|---|---|---|

| Screw Diameter | inch (mm) | A: 0.87 (22) B: 1.02 (26) BB: 1.10 (28) |

| Injection Capacity | inch³ (cm³) (oz) | 2.1 (35) (1.2) 3.0 (49) (1.6) 3.5 (57) (1.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40100 (276) (2820) 30290 (209) (2130) 26170 (180) (1840) |

| Clamping Force | USton (kN) (tf) | 72 (641) (65) |

| Clamping Stroke | inch (mm) | 16.9 (430) |

| Min. Mold Thickness | inch (mm) | 6.7 (170) |

| Max. Daylight Opening | inch (mm) | 23.6 (600) |

| Tie Bar Clearance (H×V) | inch (mm) | 12.8 x 12.8 (325 x 325) |

| Die Plate Dimensions (H×V) | inch (mm) | 18.8 x 18.8 (478 x 478) |

| Ejector Stroke | inch (mm) | 2.8 (70) |

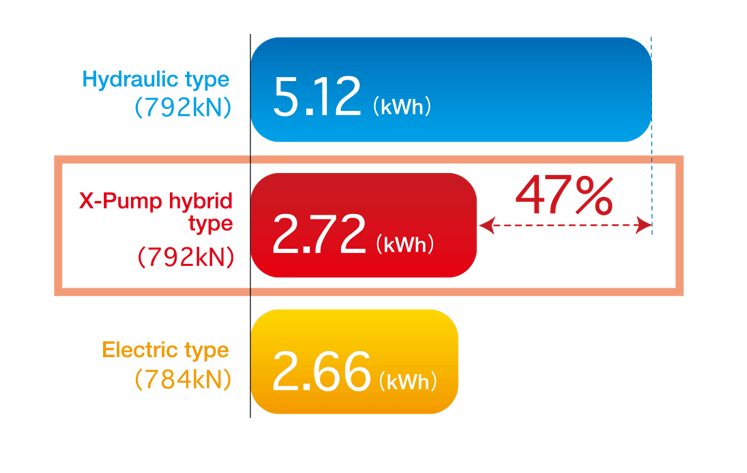

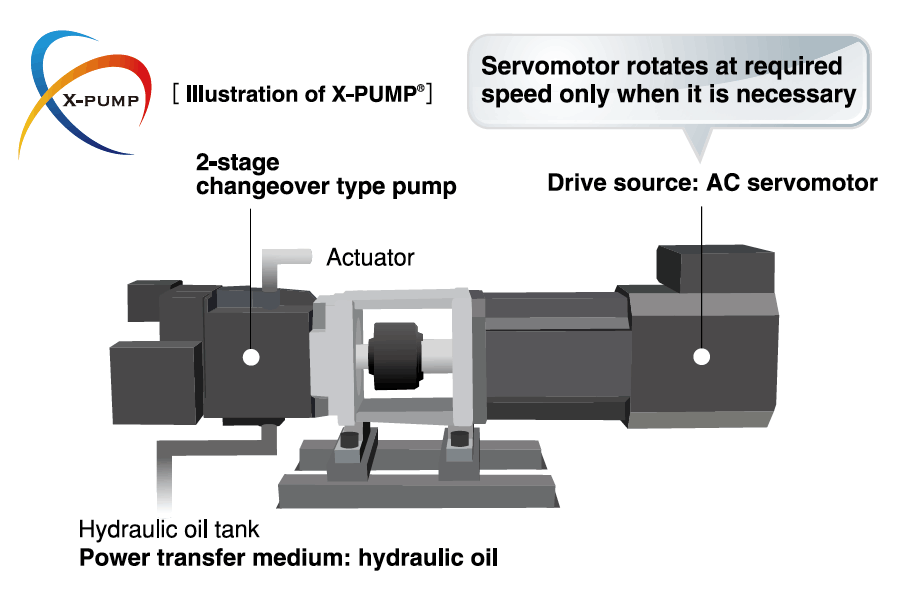

A: The “X-Pump” is an innovative hybrid pump system that combines the strengths of hydraulic and electric injection molding machines. It offers energy-saving operation and quick response times comparable to electric machines, while maintaining the durability and low maintenance benefits of hydraulic systems.

A: The PNX-III Series’ hybrid design provides:

A: The PNX-III Series offers models with clamping forces of 405 kN (41 U.S. tons) and 641 kN (65 U.S. tons), suitable for various molding requirements.

A: The “X-Pump” system operates the servomotor only when necessary, leading to significant energy savings and efficiency comparable to electric injection molding machines.

A: The PNX-III Series is versatile and can handle a wide range of injection velocities, from ultra-low to high-speed, making it ideal for various molding applications, including precision components and general-purpose products.