The TapXcell Linear from ANCA is a high-precision machine tool designed to automate tap manufacturing and resharpening. It combines advanced automation, precision grinding, and durability for unmatched performance.

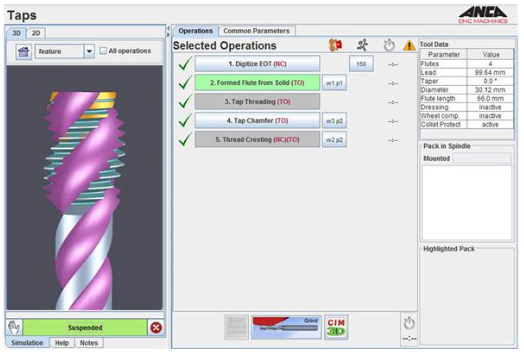

The TapXcell Linear by ANCA is a versatile solution in the tap grinding industry, designed to simplify the entire tap manufacturing process. It integrates cutting-edge linear motor technology, offering unparalleled precision, reliability, and efficiency. This machine ensures high-quality threading tools, making it indispensable for industries requiring consistent and durable taps. Its innovative design supports both small and large tap production.

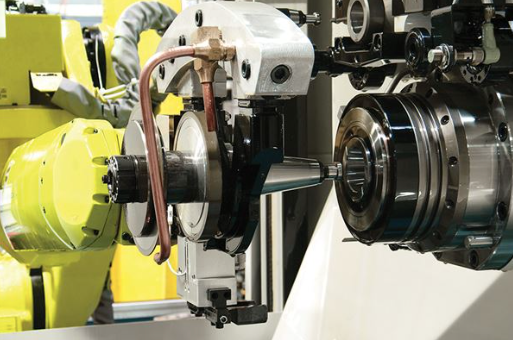

The TapXcell Linear boasts a six-station robot loader for seamless automation, enhancing productivity for high-volume production. Its linear motors ensure smooth motion and exceptional grinding accuracy. The machine supports all tap sizes and offers multi-functional grinding, reducing setup time. The integrated system ensures precision, speed, and reliability, setting new industry standards.

TapXcell Linear automates the tap grinding process for enhanced efficiency and cost savings. Its precision-driven design ensures consistent, high-quality taps for various industries. Ideal for manufacturers needing reliable threading solutions, it provides long-term value through innovative technology and productivity.

Click the dropdowns below to view detailed specifications for the TapXcell Linear.

| TapX Linear Specifications | |

|---|---|

| Machine Structure | Bi-symmetrical gantry |

| Spindle Power | 37 kW (49 HP) peak, 15 kW (25 HP) S1 |

| Wheel Packs | 2 x Ø 203 mm (8”) max |

| Tool (Shank) Diameter | Productive up to M50 |

| Maximum Tool Length | Max overall tap length 230 mm; flute length may vary depending on tooling |

| Loader Type | RoboMate (optional) |

| Maximum Tool Capacity (with loader) | M3 – 630; M6 – 630; M16 – 360; M30 – 120 |

| Drive System | X, Y, and Z axis – LinX linear motor; A & C axis – direct drive motor |

| Dimensions (W x D x H) | 2561 mm (100.8”) W x 1500 mm (59”) D x 2272 mm (89.4”) H; with RoboMate: 2260 mm (89”) D |

| CNC Details | ANCA AMC5, EtherCAT, high performance CNC, 8GB RAM, 64GB SSD, i7 Processor, Windows 8 |

A: It can grind and resharpen taps of all sizes, making it versatile for various applications.

A: The robot loader automates loading and unloading, streamlining production for high-volume operations.

A: Yes, the TapXcell Linear is flexible and supports custom tap manufacturing.

A: Industries like automotive, aerospace, and manufacturing that require precise threading tools benefit significantly.

A: Linear motors provide smooth, precise movements, ensuring consistent grinding accuracy and superior tap quality.