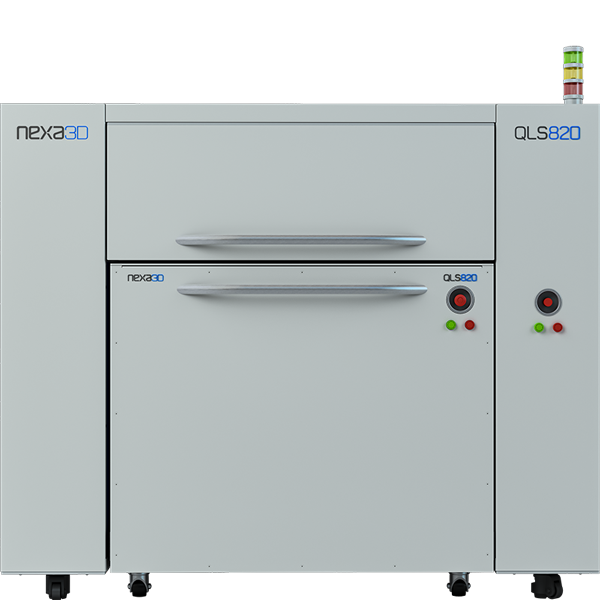

Nexa3D’s SLS 3D printers are designed to deliver high-speed, precision additive manufacturing for industrial applications. These advanced printers combine speed, accuracy, and scalability, redefining possibilities for 3D printing in diverse industries.