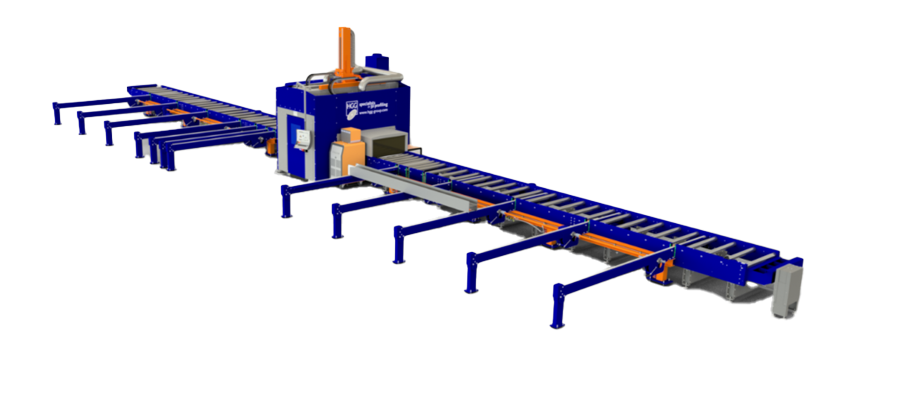

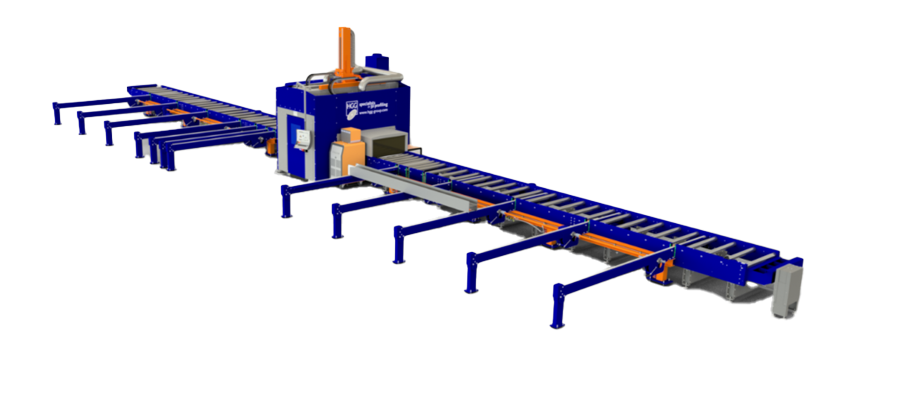

The RPC 1200 Mk3 by HGG is the ultimate robotic plasma cutting machine, designed for precise, efficient structural steel processing. Perfect for reducing waste and boosting productivity in fabrication.

The RPC 1200 Mk3 revolutionizes structural steel fabrication with robotic precision and plasma cutting technology. This advanced machine caters to industries requiring highly accurate profiles for construction, shipbuilding, and other heavy steel applications. Its versatility in cutting beams, tubes, and more makes it a game-changer in productivity and efficiency.

The RPC 1200 Mk3 delivers unparalleled plasma cutting precision. It supports a wide range of profiles, ensures minimal material waste, and integrates seamlessly with production lines. Automated processes, 3D CAD compatibility, and intelligent design features optimize steel processing, saving time and costs while enhancing reliability.

The RPC 1200 Mk3 enhances steel processing by delivering unmatched precision and speed. Its automated capabilities reduce labor costs, improve material utilization, and ensure consistent quality, making it ideal for industries aiming for superior fabrication standards.

Click the dropdowns below to view detailed specifications for the RPC 1200 Mk3.

| RPC 1200 Mk3 Specifications | |

|---|---|

| Profile Types | Beams, Tubes, Angles, Channels, Square Tubes, Plates, T-bars, Bulb Flats |

| Minimum Profile Size | 100 x 5 mm (4″ x 0.2″) |

| Maximum Profile Size | 1220 x 430 mm (48″ x 17″) |

| Cutting Process | High-Definition Plasma Cutting |

| Marking Options | Plasma Marking with Cutting Torch |

| Power Source | Hypertherm or Kjellberg |

| Additional Features | 3D Laser Measurement, Automated Cutting and Marking, Integration with 3D CAD Software |

A: It supports beams, tubes, angles, channels, and custom profiles, ensuring versatility for various steel fabrication needs.

A: Its automated cutting reduces manual labor, minimizes material waste, and speeds up production times, boosting overall efficiency.

A: Yes, the RPC 1200 Mk3 seamlessly integrates with 3D CAD software for streamlined design-to-production workflows.

A: Construction, shipbuilding, offshore, and heavy fabrication industries gain significant productivity and quality advantages.

A: Regular cleaning and inspection of cutting components and software updates ensure optimal performance and longevity.