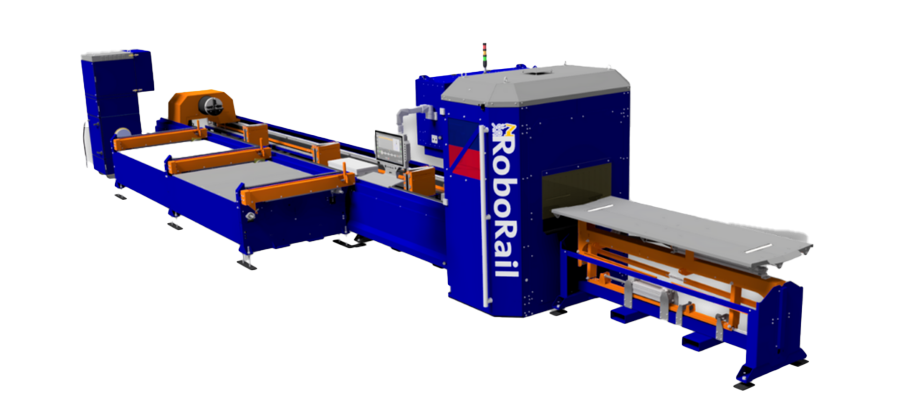

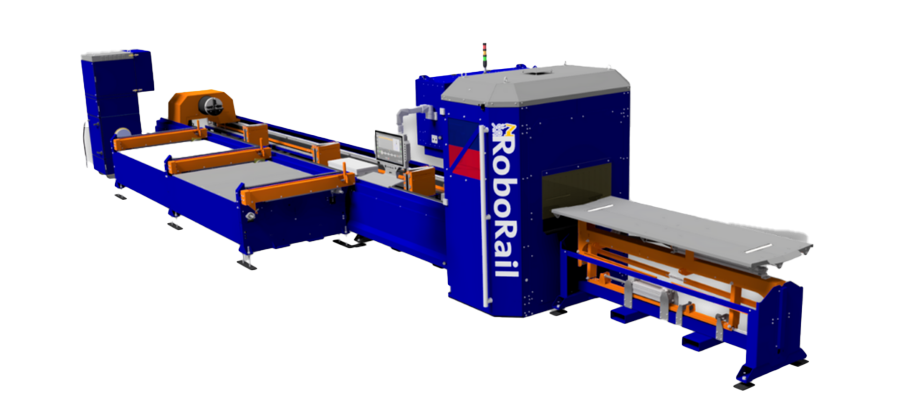

RoboRail from HGG Group is a cutting-edge robotic steel profiling system designed for precise, automated, and efficient operations in the steel industry, streamlining production with innovative technology.

RoboRail, offered by HGG Group, revolutionizes steel profiling with advanced automation. Designed for industries requiring high-quality cuts, it combines precision, speed, and versatility to handle diverse profiles. This robotic system sets new standards in steel manufacturing, reducing waste and boosting efficiency, making it indispensable for modern production lines.

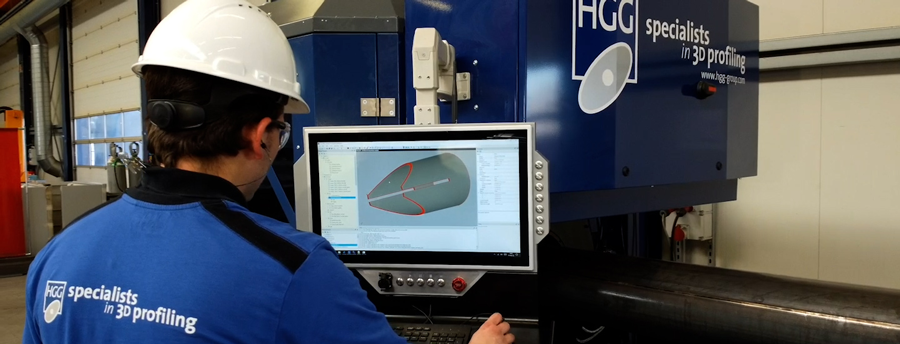

RoboRail delivers unparalleled accuracy in steel profiling through advanced robotic technology. It processes complex profiles with precision, automates workflows to enhance productivity, and supports diverse material requirements. Its user-friendly design ensures easy integration into existing setups while minimizing downtime. The system’s adaptability and efficiency make it a top choice in the steel industry.

RoboRail optimizes steel production by reducing waste, improving cutting precision, and enhancing workflow efficiency. Customers benefit from reduced operational costs, increased productivity, and the flexibility to handle complex projects. Its advanced automation transforms operations, delivering consistent, high-quality results in every production run.

Click the dropdowns below to view detailed specifications for the RoboRail.

| RoboRail Specifications | ||

|---|---|---|

| Profile Type | Minimum Size | Maximum Size |

| Pipe Diameter | 1 inch (25 mm) | 10 inches (250 mm) |

| Box Section | 1 x 1 inch (25 x 25 mm) | 8 x 8 inches (200 x 200 mm) |

| Channel Width | 3 inches (75 mm) | 12 inches (300 mm) |

| Angle Size | 1 x 1 inch (25 x 25 mm) | 8 x 8 inches (200 x 200 mm) |

| Material Thickness | 1/8 inch (3 mm) to 3/4 inch (20 mm) | |

| Infeed Length | Up to 24 feet (7,315 mm) | |

| Outfeed Length | Up to 8 feet (2,500 mm) | |

| Maximum Infeed Weight | 882 lbs (400 kg) | |

| Cutting Process | Plasma Cutting | |

| Marking Options | Layout Marking Available | |

| CAD Integration | Compatible with SDS2, Tekla, SolidWorks, Inventor, and more | |

A: RoboRail automates steel profiling, ensuring precise cuts and efficient workflows for industries requiring high-quality production.

A: Its robotic system automates tasks, reduces manual effort, and minimizes errors, leading to faster production and lower costs.

A: Yes, RoboRail is designed to process diverse and intricate steel profiles with exceptional precision.

A: Absolutely, RoboRail’s user-friendly design ensures seamless integration into existing production setups with minimal downtime.

A: Industries like construction, shipbuilding, and industrial manufacturing gain from its efficiency, precision, and versatility.