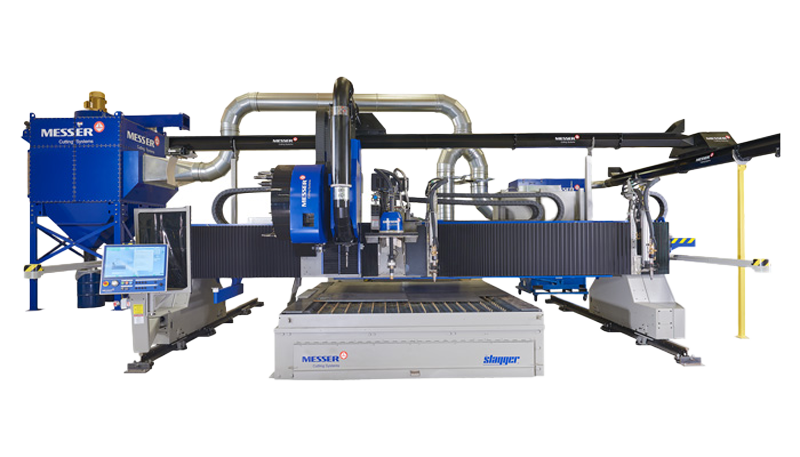

The MPC Series from MESSER Cutting Systems delivers unmatched precision and reliability for cutting applications, redefining efficiency and productivity in the industry with advanced technology.

The MPC Series by MESSER Cutting Systems is a top-tier solution for high-precision cutting applications. Designed for demanding industries, this cutting-edge machinery ensures maximum productivity with superior performance. Its innovative design and features make it a leader in the metal cutting industry, driving efficiency and delivering exceptional results.

The MPC Series excels with precision cutting, high-speed operation, and robust construction. It supports plasma and oxyfuel cutting, offering flexibility for diverse applications. Its intuitive controls and advanced software enhance accuracy, while ergonomic design ensures ease of use, making it an industry benchmark.

The MPC Series enhances cutting efficiency, improves accuracy, and supports complex projects with ease. It reduces downtime with its reliable operation and offers unmatched versatility, making it a trusted choice for professionals needing precise and high-performance cutting solutions.

Click the dropdowns below to view detailed specifications for the MPC Series.

| MPC2000 Specifications | |

|---|---|

| Cutting Width | 8′ (2.438m) to 28′ (8.534m) |

| Cutting Length | Up to 200′ (60.69m) |

| Contouring Speeds | Up to 400 ipm |

| Positioning Speeds | Up to 1400 ipm |

| Material Thickness Capacity | 26 ga. to 8″ (203.2mm), dependent on process |

| Materials Processed | Mild Steel, Stainless Steel, Aluminum |

| Optional Features |

|

| MPC2000 MC Specifications | |

|---|---|

| Cutting Width | 12′ (3.657m) to 28′ (8.534m) |

| Cutting Length | Up to 200′ (60.69m) |

| Contouring Speeds | Up to 400 ipm |

| Positioning Speeds | Up to 1400 ipm |

| Material Thickness Capacity | 26 ga. to 8″ (203.2mm), dependent on process |

| Materials Processed | Mild Steel, Structural Steel, Stainless Steel, Aluminum |

| Drilling Capacity | Up to 2.5″ diameter on 6″ thick mild steel |

| Tapping Capacity | Up to 1.5″ diameter |

| Milling Capability | X-Y Milling |

| Chip Extraction System | High-suction vacuum system with collection hopper |

| Optional Features |

|

A: The MPC Series supports plasma and oxyfuel cutting, catering to a wide range of material thicknesses and applications.

A: With advanced software and intuitive controls, the MPC Series achieves high accuracy and repeatable results.

A: Yes, its robust construction and performance make it ideal for demanding industrial use.

A:The MPC Series is designed to cut various metals, including steel, aluminum, and more.

A: Yes, it includes advanced software for seamless integration and optimized cutting operations.